LED displays are widely popular for their high brightness, flexible installation and dynamic video display capabilities. When choosing to buy or rent LED displays, customers are usually concerned about their lifespan.

Compared to LCD screens, LED displays have a longer lifespan, which means that once the investment is made, there is a long-term financial return. So, how to effectively extend the service life of LED video wall?

Exploring the durability of LED screens

The durability of LED display screen can be understood from several perspectives, including economic life, technical life, actual life and average life.

Economic Lifespan

The economic life of an LED display is primarily used to determine when to depreciate and replace.

This concept is based on the average annual minimum cost of use of the LED display to calculate its effective life.

Technical Lifespan

Technical life refers to the period of time during which a product remains technologically advanced.

This covers the entire process of LED screens from entering the market to being replaced by more technologically advanced products.

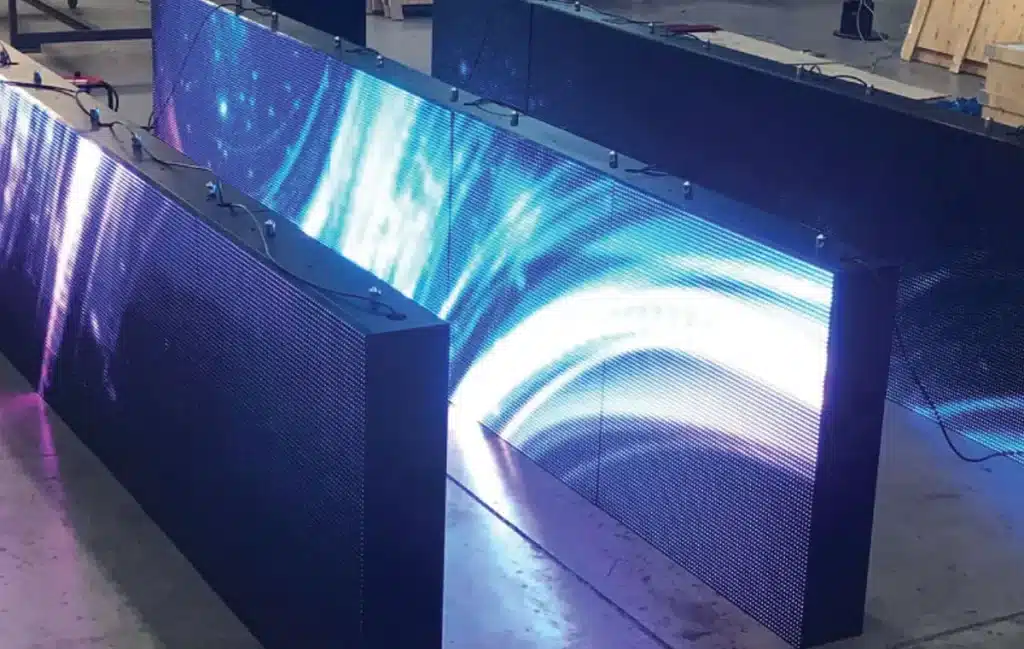

Currently, LED displays are widely used in a variety of indoor and outdoor settings, such as advertising, entertainment, sporting events and film and television production.

Service Lifespan

The service life of an LED display is defined as the period of time from the start of its use to the failure or damage of the device.

In this blog, we mainly focus on its service life.

Average Lifespan

Although the theoretical lifespan of LEDs can be up to 100,000 hours, the average lifespan of LED displays is usually between 6 and 8 years, taking into account the influence of the actual usage environment.

Key factors affecting LED screen life

Knowing the factors that affect LED screen life can help you pay more attention to the performance and durability of the product when you are shopping.

Below we will explore in detail what key factors affect the life of LED display.

Temperature

LED screen consists of several components, including light-emitting devices, switching power supply, and various electronic control boards.

The life of these components is directly related to the life of the entire LED display, and their normal operation is highly dependent on the appropriate temperature. If the display of the working environment temperature or heat dissipation design is not reasonable, resulting in the working temperature exceeds the safety range of the product regulations, the life of the display will be significantly shortened.

Dust

Accumulation of dust will hinder the heat dissipation effect of electronic components, as mentioned earlier, overheating will lead to damage to the electronic components inside the display. Therefore, regular cleaning of the dust on the surface of the display can reduce the risk of failure.

When cleaning the dust inside the case, be sure to disconnect the power supply and operate with caution. It is not recommended to disassemble the LED light box by yourself unless you are a maintenance professional.

Humidity

Humidity is an important factor that affects the life of the LED display.

Moisture may penetrate into various precision electronic components through the encapsulation materials, resulting in short circuit of internal circuits, such as lamp beads, ICs, PCBs, etc.

Corrosive Gases

In areas near the ocean, special consideration needs to be given to the impact of salt-laden air on the display, as it can accelerate the corrosion of metal parts. The volumetric conductivity and dissipation factor of the insulating material will also increase after absorbing moisture. For this reason, some protective measures can be taken, such as the use of corrosion-resistant case materials, the application of special coating seals.

Vibration

During transportation or use, electronic equipment will inevitably be hit or scratched. Good anti-collision design and anti-vibration performance can protect the integrity of the LED screen, thus significantly extending its service life.

Load

Components such as integrated chips, LED beads, switching power supplies, etc. need to operate under rated loads. The aging of electronic components will undoubtedly affect the service life of the entire product.

How To Extend The Service Life Of Led Display?

Choosing LED display products with a long service life can attract more customers and at the same time reduce the replacement cost, bringing longer-term economic benefits.

So, how to ensure that the LED display has a longer service life?

Selection Of High-Quality Materials

High-quality LED display products rely on high-quality raw materials. The quality of components such as lamp beads, ICs and power supplies not only determines the display effect of the screen, but also directly affects the service life of the product.

Therefore, if your budget allows, it is recommended that you choose a well-known brand of high-quality raw materials in the industry.

Implementation Of Standardized Manufacturing

Having a modern, standardized SMT production workshop and assembly workshop can ensure the production of high-quality products. During the production process, anti-static measures should be taken, such as workers wearing static rings and anti-static work clothes.

Strict Aging Test

LED display module and the whole screen must undergo strict aging test before delivery to customers. Aging test is a key step to detect potential problems before delivery, including white balance test and video test. aging test of LED display includes white light aging (4 hours) and video aging (48 hours).

The Importance Of Routine Maintenance

In addition, the routine maintenance of LED display is equally important. Regularly clean the dust on the screen and avoid playing high-current images such as all-white and all-green for a long time to prevent failures. When playing content at night, the screen brightness should be adjusted according to the environment.

To summarize, the strategy to extend the life of LED display involves many aspects from production to aging test to daily maintenance.