Behind the LED display, there are two packaging technology masters – SMD and MIP. They each provide solid support for the high performance and wide application of LED display. Today, let us unveil their mystery and see what the difference is between these two packaging technologies and how to choose.

What Is SMD Packaging Technology In LED Display?

1. What is SMD packaging technology?

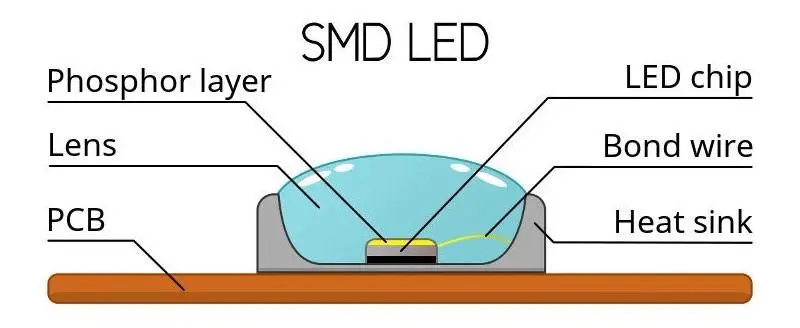

SMD, the full name is Surface Mounted Devices. It is to stick small LED lamp beads directly on the circuit board. These lamp beads contain LED chips, brackets, leads and other components. Through precise packaging technology, they form compact and efficient light-emitting units. When you see the flashing light on the LED display, there may be thousands of SMD lamp beads working behind it.

2. What are the advantages and disadvantages of SMD packaging technology?

⑴Advantages:

①Mature technology: After years of development, SMD packaging technology has become very mature, with low production costs and is suitable for large-scale production.

②Easy maintenance: If a certain lamp bead is broken, it can be easily replaced individually without affecting the normal operation of other lamp beads.

③Good heat dissipation effect: The lamp beads are in direct contact with the circuit board, which is conducive to the rapid dissipation of heat.

⑵Disadvantages:

① Low protection level: The lamp beads are exposed and easily affected by the external environment, such as moisture, dust, static electricity, etc.

②Image quality limitation: Since there is a certain distance between the lamp beads, there are certain limitations in achieving ultra-high-definition image quality.

3. Application scenarios of SMD packaged LED display

SMD packaging technology is widely used in indoor and outdoor LED displays in various industries, such as security monitoring, command and dispatch, exhibition display, smart conference, commercial advertising, etc.

What Is MIP Packaging Technology In LED Display?

1. What is MIP packaging technology?

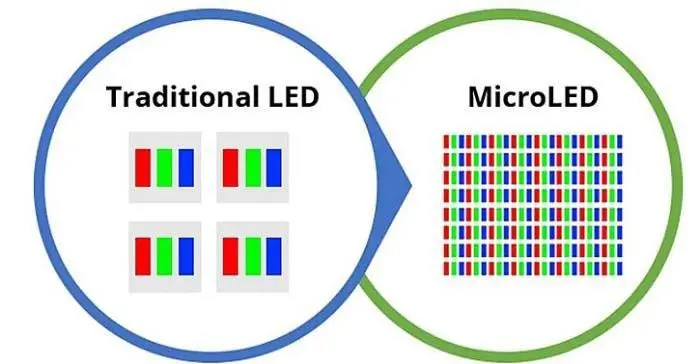

MIP, the full name of Micro LED in Package, It is a new packaging technology based on Micro LED. It first packages Micro LED chips at the chip level to form small packages, and then integrates these small packages into the display. MIP packaging technology achieves high-density integration and precise control of LED chips through advanced technologies such as mass transfer.

2. What are the advantages and disadvantages of MIP packaging technology?

⑴Advantages:

①Excellent display effect: Due to the use of extremely small Micro LED chips, MIP packaging technology can achieve extremely high brightness and contrast, and the picture is delicate and uniform.

②Low maintenance cost: MIP packaging technology makes the replacement of a single LED chip easier and faster, reducing maintenance costs.

③Excellent protection performance: The package provides comprehensive protection for the LED chip, improving the moisture-proof, dust-proof, and anti-static properties of the display.

⑵Disadvantages:

① High technical complexity: MIP packaging technology has high requirements for mass transfer and packaging accuracy, and the production cost is relatively high.

② Low market penetration: Currently, MIP packaging technology is still in its early stages of development and its market penetration is not as high as that of SMD packaging technology.

3. Application scenarios of MIP packaged LED display

MIP packaging technology is particularly suitable for scenes with extremely high requirements for image quality, such as high-end commercial displays, virtual shooting, movie screens, etc. As the technology continues to mature and costs decrease, MIP packaging technology is expected to be widely used in more fields.

What Are the Differences Between SMD and MIP Packaging Technology?

1. Packaging Principle

SMD is to directly attach LED lamp beads to the circuit board; while MIP is to package the Micro LED chip at the chip level and then integrate it into the display screen.

2. Display Effect

MIP packaging technology uses smaller Micro LED chips, so it can achieve higher brightness and contrast, and the picture is more delicate and uniform.

3. Protection Performance

MIP packaging technology has excellent protection performance and can better resist the influence of the external environment; while the protection level of SMD packaging technology is relatively low.

4. Application Scenarios

SMD packaging technology is widely used in simple and ordinary indoor and outdoor LED display screens in various industries; while MIP packaging technology is more suitable for high-end scenarios with extremely high image quality requirements.

5. Comparison of Advantages and Disadvantages

| Packaging Technology | Advantage | Disadvantages |

| SMD | 1. Mature and stable technology, low production cost

2. Easy maintenance, single lamp beads can be replaced

3. Good heat dissipation effect | 1. The protection level is relatively low and easily affected by the external environment

2. There are certain limitations in achieving ultra-high-definition image quality |

| MIP | 1. Good display effect, excellent brightness, contrast and color consistency

2. Low maintenance requirements, broken lamp beads can be replaced individually

3. Excellent protection performance, strong dustproof, moisture-proof and anti-static performance

4. Excellent heat dissipation performance, low power consumption and temperature rise | 1. High technical complexity and relatively high production cost

2. Market penetration is not as good as SMD packaging technology |

How to Choose Between SMD and MIP Packaging Technology?

When choosing between SMD and MIP packaging technology, you need to consider factors such as application scenarios, budget, and display effects. For scenarios with limited budgets and not particularly high requirements for image quality, SMD packaging technology is a good choice; while for high-end scenarios that pursue extreme image quality and have a relatively ample budget, MIP packaging technology is more advantageous.

With the continuous advancement of technology and the continuous expansion of the market, both SMD and MIP packaging technologies will usher in a broader development prospect. SMD packaging technology will continue to play its mature, stable and cost advantages, occupying an important position in the low-end and mid-end markets; while MIP packaging technology will gradually penetrate into the high-end market with its excellent display effect and excellent protection performance.If you need help and want to inquire What Are Difference Between SMD Vs MIP LED Technology? please message us at manager@[email protected]